| Sign In | Join Free | My udpf.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My udpf.com |

|

Brand Name : AOXUANZG

Model Number : WC67Y-100T/3200

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : $13000/unit

Payment Terms : L/C, T/T, Western Union, D/P, D/A

Supply Ability : 500sets/Year

Delivery Time : 20-30 days

Packaging Details : It will be wrapped with plastic film and then loaded into a 40' container.

Control System : TP10S

Machine Type : CNC Press Brake

Nominal Pressure : 1000KN

Worktable Length : 3200mm

Distance Between Housings : 2600mm

Throat Depth : 250mm

RAM Stroke : 130mm

Max. Open Height : 350mm

Strokes : ≥8times/min

Main Motor : 7.5kw

Breif Introduction

Hydraulic bending is a common metalworking machine used to bend metal sheets into the desired shape.

It is an essential basic machine in the sheet metal processing industry.

During the bending process, the metal sheet is placed on a workbench and can be bent into the desired angle and shape by applying pressure.

The press brake usually consists of an upper punch and a lower die, and the upper punch bends the metal sheet by applying downward pressure.

This technology is widely used in the production of various products, such as automotive parts, home appliances, building materials, etc.

These machines can not only improve product quality and consistency, but also greatly improve production efficiency by adjusting accuracy.

Compared with traditional manual bending, press brakes have higher production efficiency and accuracy.

Therefore, it has received more and more attention and is widely used in various small-scale to large-scale production projects.

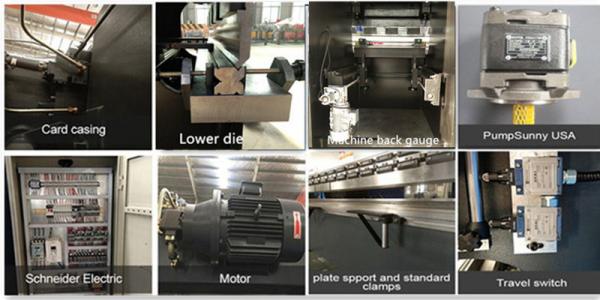

High precision backguage

Germany Bosch Rexroth safety valve

Germany EMB Hose connector

Schneider Electric Syste

RV reducer motor working table compensation (Optional)

Compensation device on workbench (Optional)

Quick mold clamping device

Details:

Technical Parameters:

| Model | Nominal pressure (KN) | Worktable Length (mm) | Columns Distance (mm) | Throat | Slider | Max | Main | Dimension |

| Depth | Stroke | Open | motor | L x W x H | ||||

| (mm) | (mm) | height | Power | (mm) | ||||

| (mm) | (KW) | |||||||

| WC67Y/K-30/1600 | 300 | 1600 | 1280 | 200 | 80 | 190 | 3 | 1700×900×1650 |

| WC67Y/K-30/2000 | 300 | 2000 | 1280 | 200 | 80 | 190 | 3 | 1700×900×1650 |

| WC67Y/K-40/2500 | 400 | 2500 | 1900 | 280 | 100 | 320 | 5.5 | 2600×1100×1900 |

| WC67Y/K-63/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 5.5 | 3100×1450×2050 |

| WC67Y/K-80/3200 | 800 | 3200 | 2700 | 350 | 170 | 380 | 7.5 | 3500×1550×2100 |

| WC67Y/K-100/3200 | 1000 | 3200 | 2700 | 400 | 200 | 420 | 7.5 | 3500×1580×2400 |

| WC67Y/K-160/3200 | 1600 | 3200 | 2700 | 400 | 200 | 420 | 11 | 3500×1650×2550 |

| WC67Y/K-200/3200 | 2000 | 3200 | 2700 | 400 | 200 | 420 | 15 | 3500×1680×2550 |

| WC67Y/K-250/3200 | 2500 | 3200 | 2700 | 400 | 200 | 420 | 15 | 3500×1700×2600 |

| WC67Y/K-320/3200 | 3200 | 3200 | 2700 | 400 | 200 | 420 | 22 | 3500×1800×2730 |

| WC67Y/K-400/4000 | 4000 | 4000 | 3500 | 500 | 320 | 600 | 30 | 4300×2450×3500 |

| WC67Y/K-500/5000 | 5000 | 5000 | 3900 | 500 | 320 | 600 | 37 | 5400×2810×4300 |

| WC67Y/K-500/6000 | 5000 | 6000 | 4900 | 500 | 320 | 600 | 37 | 6500×2810×4300 |

| WC67Y/K-500/7000 | 5000 | 7000 | 4900 | 500 | 320 | 600 | 37 | 7500×2810×4900 |

| WC67Y/K-600/5000 | 6000 | 5000 | 3900 | 500 | 320 | 600 | 45 | 5500×2910×4900 |

| WC67Y/K-600/6000 | 6000 | 6000 | 4900 | 500 | 320 | 600 | 45 | 6500×2910×5100 |

| WC67Y/K-600/7000 | 6000 | 7000 | 5900 | 500 | 320 | 600 | 45 | 7500×2910×5200 |

| WC67Y/K-800/6000 | 8000 | 6000 | 4900 | 600 | 400 | 600 | 55 | 6500×2750 ×5300 |

| WC67Y/K-800/8000 | 8000 | 8000 | 6900 | 600 | 400 | 600 | 55 | 8500×2750×5900 |

| WC67Y/K-1000/6000 | 10000 | 6000 | 4900 | 600 | 400 | 600 | 2×37 | 6500×2800×5600 |

| WC67Y/K-1000/8000 | 10000 | 8000 | 6900 | 600 | 400 | 600 | 2×37 | 8500×2800×6100 |

| WC67Y/K-1000/10000 | 10000 | 10000 | 8000 | 600 | 400 | 600 | 2×37 | 10500×2800×5850 |

| WC67Y/K-1200/6000 | 12000 | 6000 | 4900 | 600 | 400 | 800 | 2×37 | 6500×3100×5850 |

| WC67Y/K-1200/8000 | 12000 | 8000 | 6900 | 600 | 400 | 800 | 2×37 | 8500×3100×7150 |

Certifications:

Packing Detail:

Each Hydraulic Press Brake with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Our workshop:

FAQ:

1. Are you the manufacture?Can we visit your factory?

We are manufacturer and we are located in Anhui,China. And we have our own design team for products design. And welcome you visit our factory and check our machine qualtiy on spot,any question will be solved on spot at first time.

2.What's your main product and what is your main foreign market?

Our main products are press brake,shears machine,press,cutting machine,locking machine ,auto duct line and related products. Our main foreign market are Asia, North America, Europe, Afr

ica.

3. And are you able to update the production process Information in time after placing our order? After confirming your order ,we

would keep you updated of production details of emails and photos.

4. Can we be your agent? Yes,we are looking for Global agent we will help agent improve the market ,and supply all the service

like machine technical problem or other after-sales problem, meanwhile ,you can get big discount and commission.

5. Are you provide product metal parts and provide us technical guidance? Wearing parts,Disassembly tool(free) are what we cou

ld provide.And we can give you technical guidance.Our technical staff can go abroad to provide you with technical guidance.

Contact information:

|

|

Automatic Metal Bending Machine CNC Hydraulic Bender Sheet Metal Industry 100T Economic Images |